The machining parameters in these tables have been prepared for and tested on the Tormach PCNC mills in the Elko Engineering Garage.

General Use Machining Parameters

New User Machining Parameters

The new user machining parameters are tuned to lighter machining as new users build trouble-shooting skills.

Machining Parameter Calculation

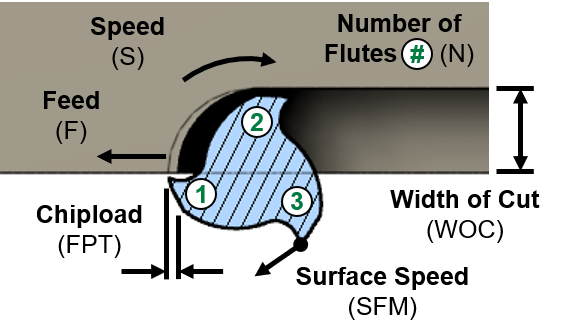

Machine Inputs

Speed

- S [RPM] (revolutions per minute)

- Rotational speed of the spindle.

Feed

- F [in/min. or mm/min.]

- Linear speed that the cutting tool moves during cutting operations.

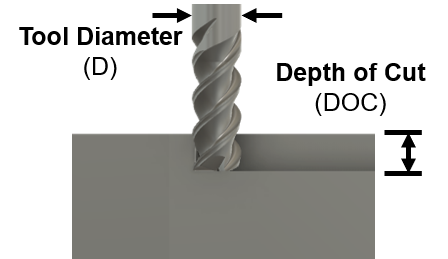

Tool Parameters

Diameter

- D [in. or mm]

- The outside diameter (OD) of the cutting tool.

Number of Flutes

- N (integer)

- The number of cutting edges on the tool.

Machining Parameters

Depth of Cut

- DOC [in. or mm] (< 200% D)

- Axial depth of tool removing material.

Width of Cut

- WOC [in. or mm] (5% D < WOC < 95% D)

- Radial width of tool removing material.

Surface Speed

- SFM [ft/min. or m/min.] (surface feet per minute)

- Linear speed at the tool cutting edge.

Chipload

- FPT [in. or mm] (feed per tooth)

- The distanced advanced by the tool between cutting edges.

Chipload (Drilling and Plunging)

- FPR [in. or mm] (feed per revolution)

- The Z-axis distanced advanced by the tool each revolution.

Calculations

Surface Speed to Speed

| Imperial | S = SFM / ((D / 12) * pi) |

| Metric | S = SFM / (D / 1000) * pi) |

Chipload to Feed

| Milling | F = S * FPT * N |

Drilling and Plunging | Fp = S* FPR |