Finding quality machining parameters is a complex but necessary process for successful machining projects.

Machining Parameter References

New User Machining Parameters

The new user machining parameters are tuned to lighter machining as new users build trouble-shooting skills.

General Use Machining Parameters

Machining Parameter Calculation

Machine Inputs

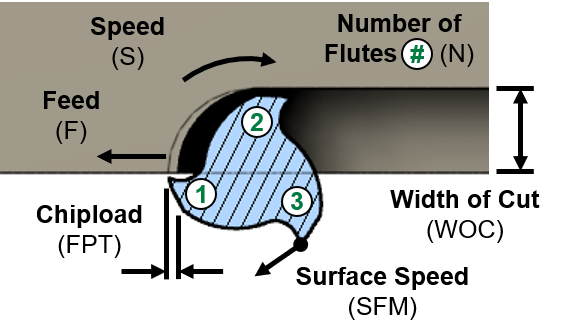

Speed

- S [RPM] (revolutions per minute)

- Rotational speed of the spindle.

Feed

- F [in/min. or mm/min.]

- Linear speed that the cutting tool moves during cutting operations.

Tool Parameters

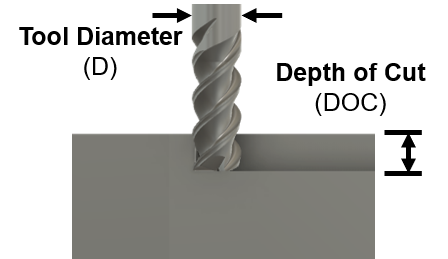

Diameter

- D [in. or mm]

- The outside diameter (OD) of the cutting tool.

Number of Flutes

- N (integer)

- The number of cutting edges on the tool.

Machining Parameters

Depth of Cut

- DOC [in. or mm] (< 200% D)

- Axial depth of tool removing material.

Width of Cut

- WOC [in. or mm] (5% D < WOC < 95% D)

- Radial width of tool removing material.

Surface Speed

- SFM [ft/min. or m/min.] (surface feet per minute)

- Linear speed at the tool cutting edge.

Chipload

- FPT [in. or mm] (feed per tooth)

- The distanced advanced by the tool between cutting edges.

Chipload (Drilling and Plunging)

- FPR [in. or mm] (feed per revolution)

- The distanced advanced by the tool each revolution.

Calculations

Surface Speed to Speed

| Imperial | S = SFM / ((D / 12) * pi) |

| Metric | S = SFM / (D / 1000) * pi) |

Chipload to Feed

| Milling | F = S * FPT * N |

Drilling and Plunging | Fp = S* FPR |