Model Specifics

| Properties | Status | Materials | About |

|---|---|---|---|

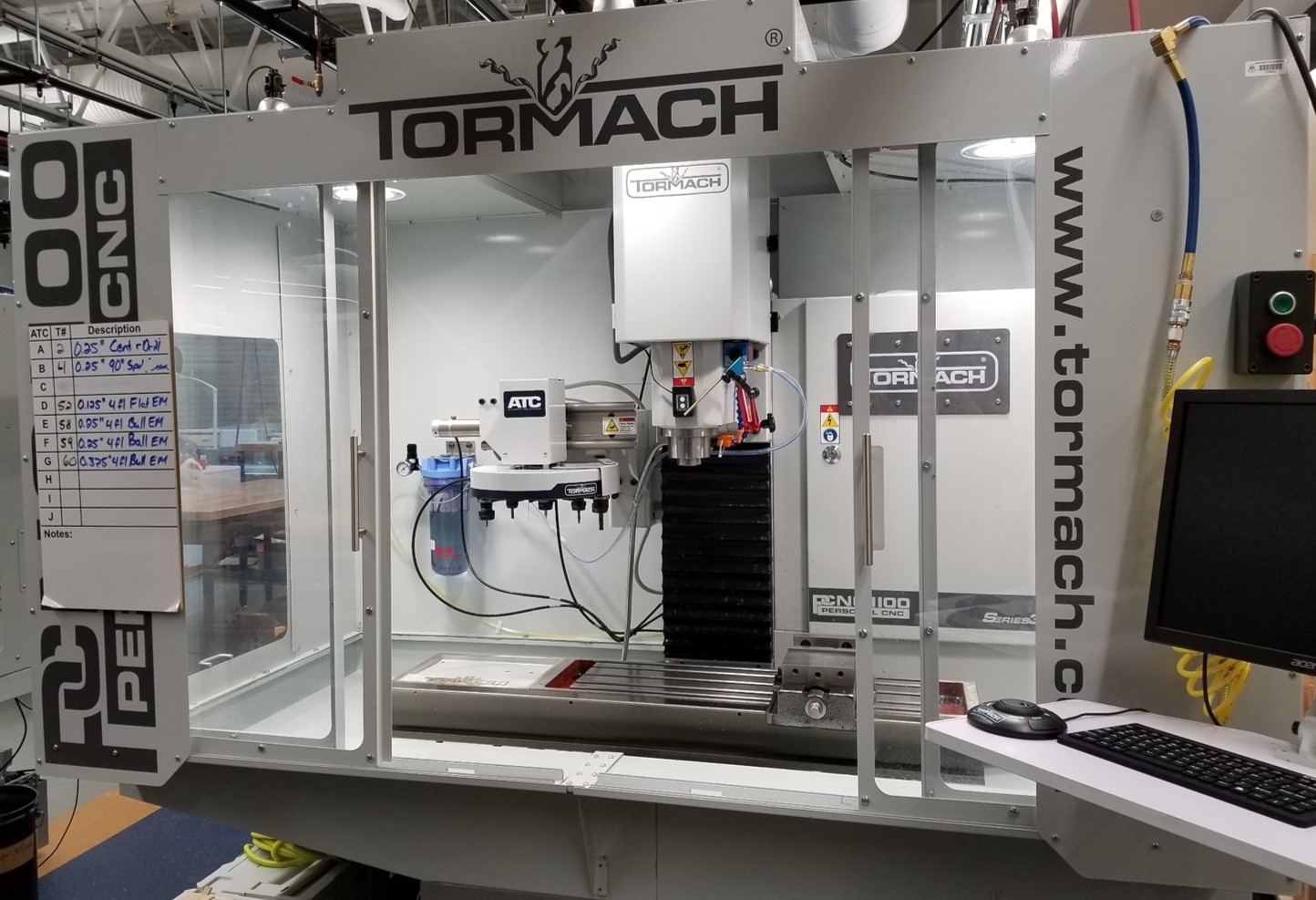

| Tormach PCNC 770 | AVAILABLE |

|

|

| Tormach PCNC 1100 | AVAILABLE |

|

|

Tormach PCNC 770

Tormach PCNC 1100

Standard Operating Procedure

Google Apps Sign-in Required

You must login to your uAlberta Google apps account to access these files.

Training

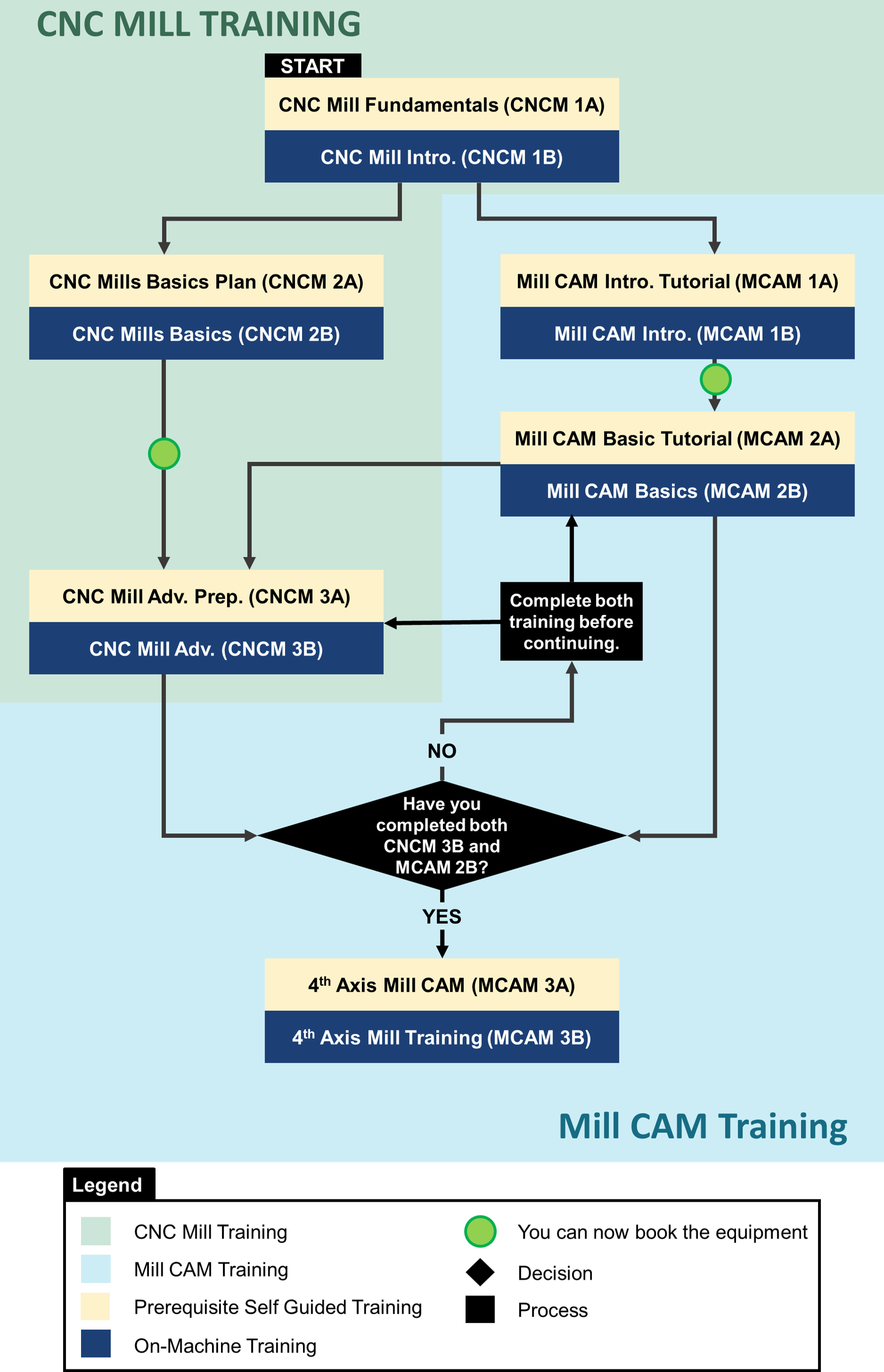

After completing at least 2 training levels (up to MCAM 1B or CNCM 2B, inclusive), the first independent use will be a shadowed session.

CNC mill training is separated into two streams - CNC mill training and mill CAM training. The flowchart below outlines the training workflow.

- CNC mill training uses the software on the machine computer to create toolpaths to machine simple parts.

- Mill CAM training uses CAD and CAM software to create toolpaths to machine complex parts.

Training is scheduled on an email request basis. Please email us at garage@ualberta.ca if you are interested in starting the CNC mill training.

CNC Mill Training

| Training | Type | Time Estimate | Prerequisites | Checklist/Document |

|---|---|---|---|---|

| CNC Mills - 1A Fundamentals | SELF-GUIDED DOCUMENT | 0.5 hrs. | None | |

| CNC Mills - 1B Intro. | ON-MACHINE | 3 hrs. | ||

| CNC Mills - 2A Basics Plan | SELF-GUIDED DOCUMENT | 1 hrs. | None | |

| CNC Mills - 2B Basics | ON-MACHINE | 2 hrs. | ||

| CNC Mills - 3A Advanced Prep. | SELF-GUIDED DOCUMENT | 0.5 hrs. | None | |

| CNC Mills - 3B Advanced | ON-MACHINE | 50 min. |

Mill CAM Training

| Training | Type | Time Estimate | Prerequisites | Checklist/Document |

|---|---|---|---|---|

| Mill CAM - 1A Intro. Tutorial | SELF-GUIDED DOCUMENT | 3 hrs. | None | |

| Mill CAM - 1B Intro. | ON-MACHINE | 3 hr. | ||

| Mill CAM - 2A Basics Tutorial | SELF-GUIDED DOCUMENT | 3 hrs. | None | |

| Mill CAM - 2B Basics | ON-MACHINE | 3 hr. |

Documentation

Google Apps Sign-in Required

You must login to your uAlberta Google apps account to access these files.